Accountability – Case Study

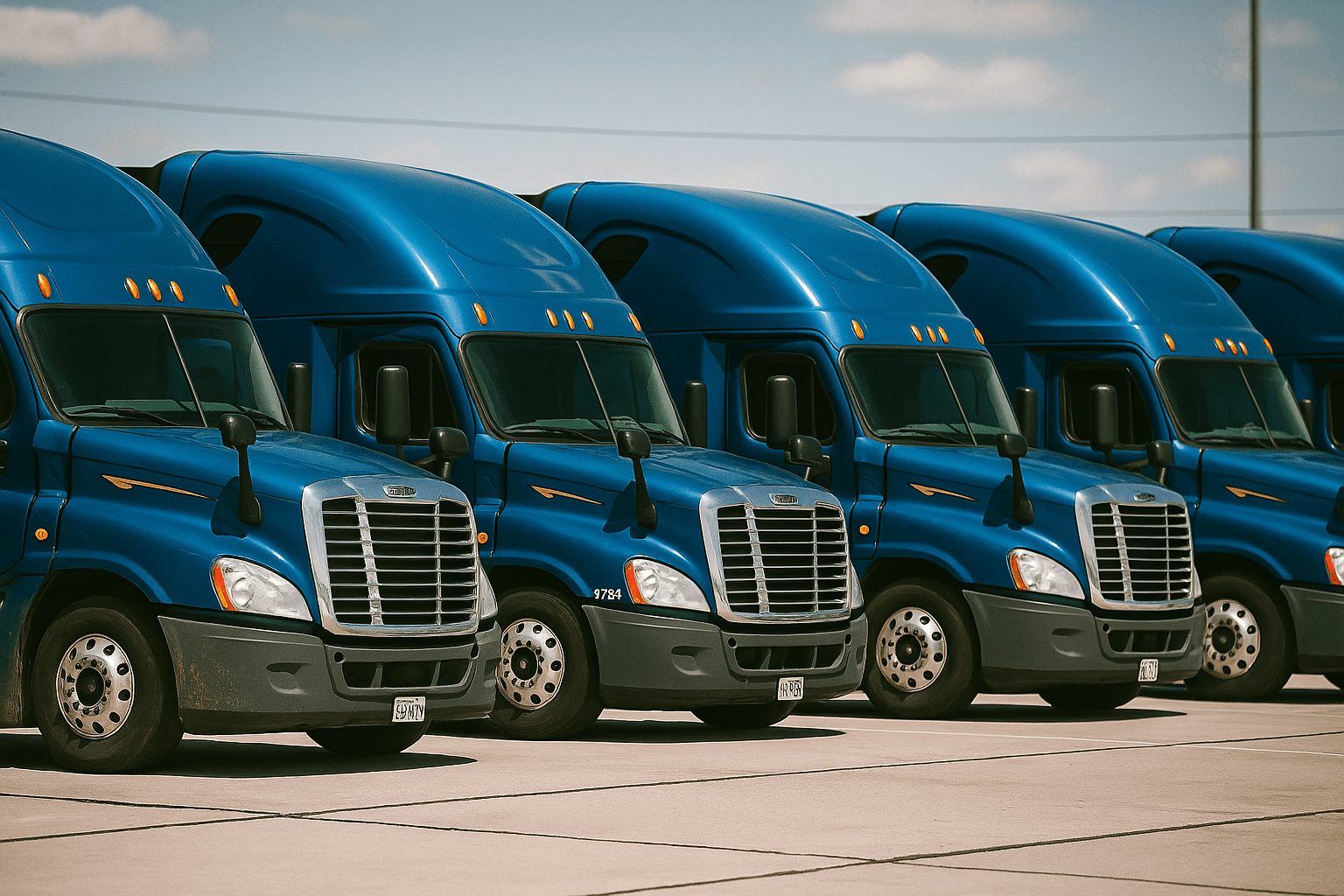

Tracking drivers and enforcing direct accountability in a busy fleet led to a 90% reduction in incidents

A trucking company was experiencing frequent accidents and traffic violations across its fleet, leading to high repair costs, mounting fines, and growing frustration for the owner.

PROBLEM

- Drivers were receiving frequent traffic tickets, including idling violations and improper parking.

- The fleet experienced a high volume of minor accidents, resulting in ongoing and costly damage.

- These recurring issues led to mounting fines, frequent repairs, and rising insurance premiums.

- Trucks were regularly taken out of service, disrupting operations and reducing fleet availability.

- The yard manager was stuck in damage control mode, focusing on repairs instead of managing the yard.

- The owner felt drivers lacked accountability and care, creating unnecessary stress and frustration.

- Visibly damaged trucks were regularly sent out on the road, presenting an unprofessional image to customers and the public.

PROBLEM

- Drivers were receiving frequent traffic tickets, including idling violations and improper parking.

- The fleet experienced a high volume of minor accidents, resulting in ongoing and costly damage.

- These recurring issues led to mounting fines, frequent repairs, and rising insurance premiums.

- Trucks were regularly taken out of service, disrupting operations and reducing fleet availability.

- The yard manager was stuck in damage control mode, focusing on repairs instead of managing the yard.

- The owner felt drivers lacked accountability and care, creating unnecessary stress and frustration.

- Visibly damaged trucks were regularly sent out on the road, presenting an unprofessional image to customers and the public.

- There was no system in place to track which driver operated which truck on a given day, making accountability nearly impossible.

- Incidents were rarely followed up on, allowing a culture of indifference to take hold.

- The yard manager lacked a clear process for monitoring truck condition before departure, so damage was often noticed only after the fact.

- Drivers were never asked to explain tickets or accidents, and many assumed there would be no consequences.

- The owner had no consistent visibility into daily fleet activity, leading to a reactive rather than preventative approach.

DISCOVERY

- There was no system in place to track which driver operated which truck on a given day, making accountability nearly impossible.

- Incidents were rarely followed up on, allowing a culture of indifference to take hold.

- The yard manager lacked a clear process for monitoring truck condition before departure, so damage was often noticed only after the fact.

- Drivers were never asked to explain tickets or accidents, and many assumed there would be no consequences.

- The owner had no consistent visibility into daily fleet activity, leading to a reactive rather than preventative approach.

DISCOVERY

SOLUTION

- A system that logs which driver is assigned to each truck on a daily basis.

- A daily photo inspection process to document the condition of each vehicle before departure.

- A policy requiring drivers to personally explain any tickets or incidents directly to the owner.

- A structure where accountability is unavoidable — every incident is tied to a specific individual.

- An internal review rhythm designed to catch patterns early and reinforce expectations consistently.

SOLUTION

- A system that logs which driver is assigned to each truck on a daily basis.

- A daily photo inspection process to document the condition of each vehicle before departure.

- A policy requiring drivers to personally explain any tickets or incidents directly to the owner.

- A structure where accountability is unavoidable — every incident is tied to a specific individual.

- An internal review rhythm designed to catch patterns early and reinforce expectations consistently.

- A new system was put in place for the Truck Dispatcher to log driver assignments each morning using a shared tracking sheet.

- The Yard Manager was instructed to perform daily photo inspections before and after dispatch, reporting any visible damage.

- Drivers were informed of the new system and the expectations tied to it.

- The accountability system was introduced clearly — drivers now understood that every incident would be traced, and the owner would expect a direct explanation.

- A weekly internal review document was added to summarize incidents, helping management monitor patterns, address concerns early, and maintain consistency.

IMPLEMENTATION

IMPLEMENTATION

- A new system was put in place for the Truck Dispatcher to log driver assignments each morning using a shared tracking sheet.

- The Yard Manager was instructed to perform daily photo inspections before and after dispatch, reporting any visible damage.

- Drivers were informed of the new system and the expectations tied to it.

- The accountability system was introduced clearly — drivers now understood that every incident would be traced, and the owner would expect a direct explanation.

- A weekly internal review document was added to summarize incidents, helping management monitor patterns, address concerns early, and maintain consistency.

RESULTS

- Reduced accidents and tickets by over 90% within weeks of implementation.

- Saved thousands of dollars in fines, repairs, and lost operational time.

- Trucks remained in service more consistently, improving scheduling and productivity.

- The owner regained control and no longer felt consumed by daily emergencies.

- A culture of accountability took hold — drivers became more responsible and proactive.

- The fleet now looks clean and well-maintained on the road, improving the company’s public image and professional reputation.

RESULTS

- Reduced accidents and tickets by over 90% within weeks of implementation.

- Saved thousands of dollars in fines, repairs, and lost operational time.

- Trucks remained in service more consistently, improving scheduling and productivity.

- The owner regained control and no longer felt consumed by daily emergencies.

- A culture of accountability took hold — drivers became more responsible and proactive.

- The fleet now looks clean and well-maintained on the road, improving the company’s public image and professional reputation.