OPTIMIZATION – Case Study

Simple Process Change That Generated $500K Additional Annual Income

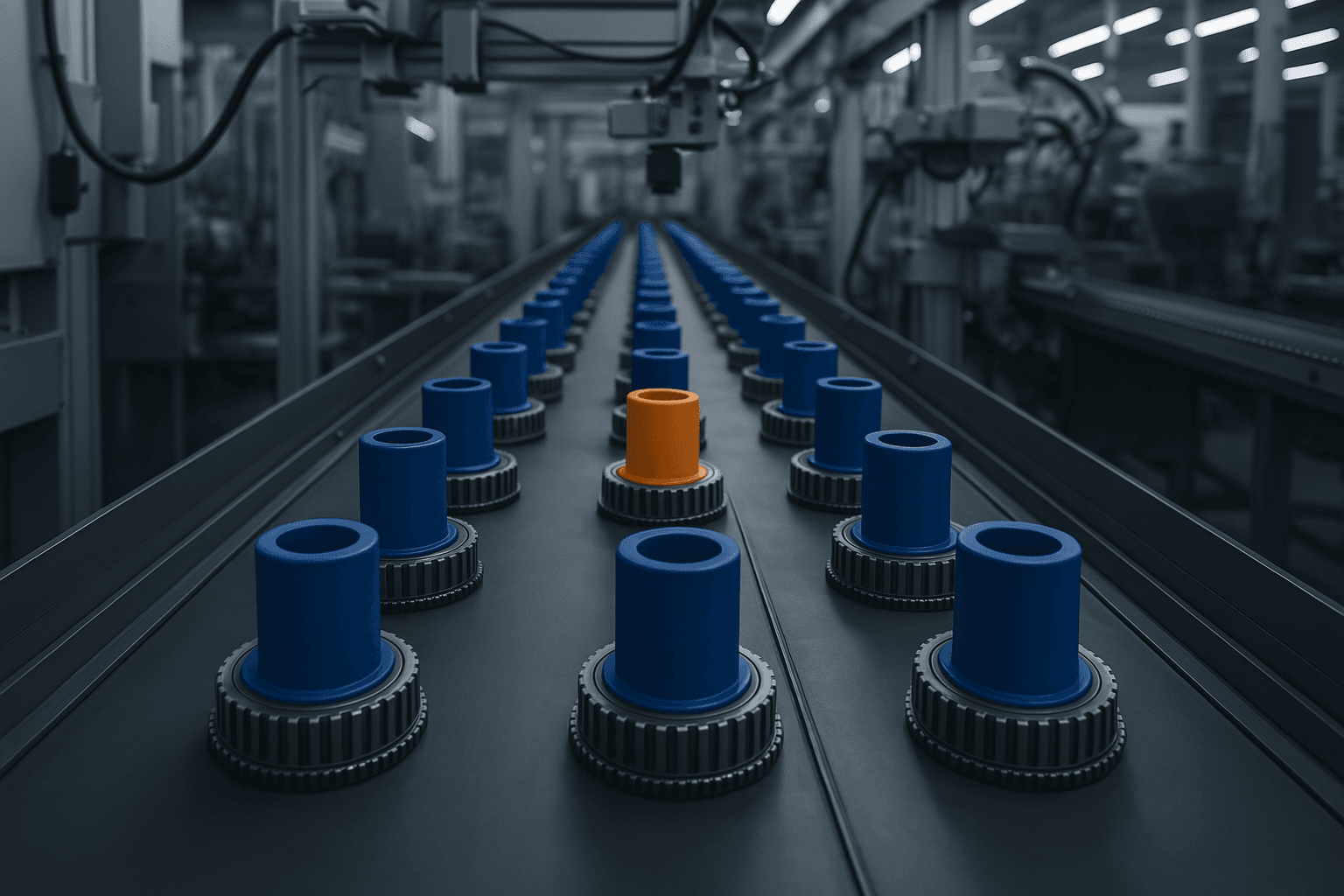

A company offered multiple products, all following the same internal process, but one product didn’t need it.

PROBLEM

PROBLEM

DISCOVERY

DISCOVERY

SOLUTION

SOLUTION

IMPLEMENTATION